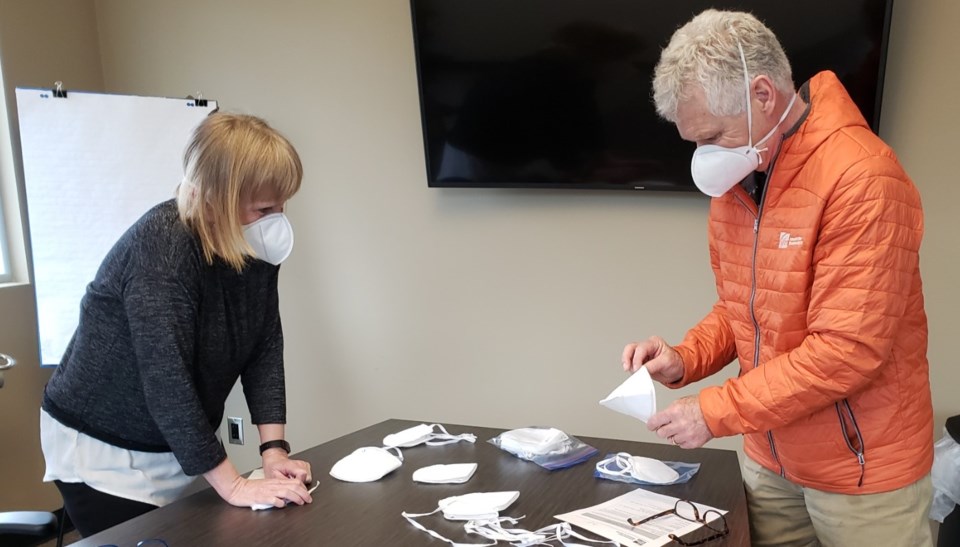

A Penetanguishene factory is ready to shift part of its product line to help supply masks to combat COVID-19.

Industrial Filter Manufacturing Ltd. president Kyle Naylor said the company knows the need for masks and gowns is very real and is ready to answer the provincial and federal government’s call to join the coronavirus fight.

“We’ve done significant retooling,” Naylor said, noting a run of 500 prototype units occurred over the weekend. “We’ve managed to get all of our ducks in a row. We’re ready to start producing immediately.”

With clients around the world, the Penetanguishene-based private company employs 35 people and specializes in manufacturing standard and custom liquid filter bags for industrial applications. Its client base ranges from beverage producers such as brewers, distillers and-fruit juice makers to those manufacturing pharmaceuticals and other products.

“We’re considered an essential service provider,” Naylor said. “Our product basically goes into every industrial process.”

But there are regulatory hurdles that must first be crossed to ensure the disposable N95 masks are certified to ASTM standards for a level 2 rating or higher.

Naylor said the company doesn’t take issue with the $7,000 application fee, but is trying to get answers as to how long the application and approval process takes.

“How do we get this done as quickly as possible?” he asked. “The application process seems more bureaucratic than scientific. There’s no sense of getting a certification that lands at our door in six months.”

Naylor said the company can potentially produce 4,000 to 5,000 masks a day while continuing to manufacture its regular product lines.

“We can access the media that’s being used for the rated mask, we just can’t get the certification for the finished product. We hope to have some assistance from the provincial and federal regulatory boards to help us expedite the process.”

And even without the official certification that isn’t required to send the product stateside, Naylor said customers are at the ready since the company’s masks are far superior to regular dust masks one can purchase at a hardware store and that people are now wearing.

As an example, he said automobile manufacturers will likely be looking for thousands of masks to keep operating since it’s impossible to observe the six-foot distancing rule on a vehicle-assembly line.

“It’s staggering to consider what the predicted consumption of masks will be,” he said. “We know there are facilities that are going to consume 4,000 to 5,000 masks a day. The demand is there, the demand is incredible.”